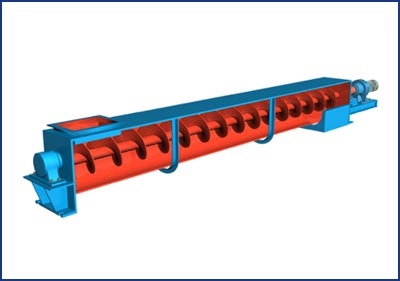

The method of cleaning the residual materials of screw conveying equipment

Screw conveyor is a kind of mechanical device used to transport materials. It is also a relatively important equipment in the production industry. It can be used to transport powder, granular, ash like materials. Generally, spiral conveying equipment is used for conveying more ash like materials. This is also the reason why the bearing has been immersed in dust for a long time. The equipment is submerged by dust and debris for a long time, which not only affects the service life of screw conveyor. It also affects its normal working efficiency. So how to clean up the residual materials of screw conveying equipment?

Before dealing with this problem, we should know why there are so many residual materials in the screw conveying equipment. The above article mentioned that this is one of the reasons. Of course, one of the main reasons for this is that the materials are easy to accumulate in the conveying process. With the increase of time, the accumulated materials will agglomerate and harden, and it is easy to produce blocking phenomenon with a long time. After the material blocking problem is found, it must be solved, otherwise it will cause the driving equipment, the load is too large, and the driving equipment will be burned down in serious cases. Therefore, these residual materials should be cleaned up in time.

Before cleaning these materials, we should first know which kind of screw conveyor you are using? This can be distinguished from the design structure. There are three main types: tubular, shaftless and grooved. Because of the different design structure, the method of cleaning residual materials is also different.

1. Pipe type spiral conveying equipment is also called screw feeding equipment. The reason for its name is that the shell looks like a circle, or a steel pipe. So there are two ways to clean up the residual materials of this kind of equipment. One is to clean directly with water. 2. Air supply for cleaning. If the method of water injection cleaning is adopted, a large amount of water should be injected into the feed inlet to remove the residual materials. If wind cleaning is used, only air pump or fan is needed. The air is also fed through the feeding port, and the wind force should be large. These two methods can achieve the purpose of cleaning the residual materials of pipe screw conveyor.

2. As the name implies, there is no central shaft in the middle of the screw conveyor. This kind of equipment is simpler than tubular equipment in cleaning materials. As long as we add a mixer in the middle of the hopper, and then add a vibrator around the hopper, the material will be scattered, and the vibration through the hopper will be discharged smoothly.

3. Trough type screw conveying equipment, this kind of equipment is generally U-shaped, the upper one has a lower groove cover. This is relatively simple. You just need to remove the fixing bolts on the groove cover, take off the cover plate, and then clean it directly. It can also be treated with air pump, but it may cause dust.

The above is the cleaning method for the residual materials of spiral conveying equipment. Before cleaning, he must stop the machine first and run the equipment empty so that it is not discharging, and then stop the machine for cleaning. In order to avoid excessive accumulation. Or clean up frequently.

Jiangmen kenchuang conveyor equipment /

-

08-24

What problems should be paid attention to when using tubular screw conveyor

Tubular screw conveyor is a kind of conveyor. Compared with ordinary conveyor, they have bucket storage box, which can transport materials on specific lines. They can be transported in various ways.

-

08-24

Selection method of pulley diameter of belt conveyor

The belt conveyor is a kind of continuous conveying equipment, which takes the conveyor belt as the traction and bearing component, and carries out the material transportation through the movement o

-

08-24

Correct operation of mesh belt conveyor

Net belt conveyor is a kind of conveyor that uses chain to carry and pull, or metal mesh belt installed on the chain to carry materials. In addition, the mesh belt conveyor is often combined with ot

-

08-24

Matters needing attention when connecting mesh belt conveyor

Mesh belt conveyor has been widely used in various industries of transportation, it from the body to the conveyor belt and then to the conveyor accessories are all metal materials, so its ultra-high